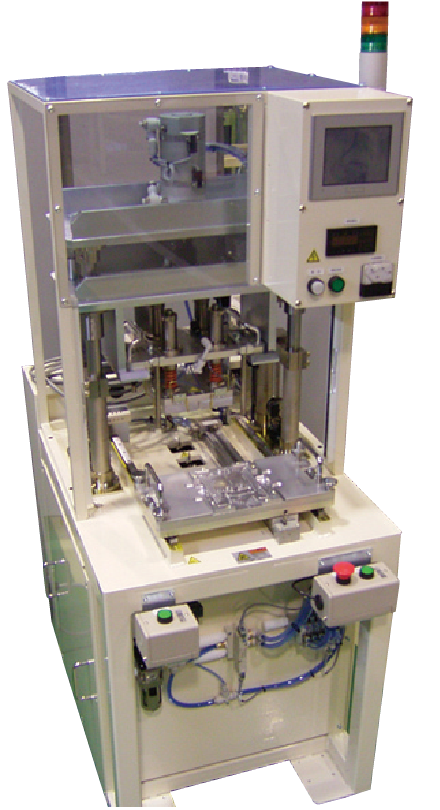

【Surface fusing】FLAT FUSION SYSTEM

The FLAT FUSION SYSTEM is our proprietary (patented) assembly technique to fuse thermoplastic materials together. Uses a heat conductive element between two parts to be fused.

Don't you have any trouble such as...?

- In case of solvent

- ・Can cut down process time of applying solvent?

・Better yield rate preventing stray solvent or wipe off?

・Can eliminate time for solvent control? - In case of ultrasonic or vibration welding.

- ・Less stress and impact to inner parts?

・Less noise in the workshop? - In case of perfect seal effect.

- ・Less man hour for screwing with packing?

・Can do perfect seal without no packing(O-ring)?

・Less man hour for assembly in seal surface? - In case defects reuse or recycle required.

- ・Separate fused surface easily.

・Can do segregation and disposal

FLAT FUSION SYSTEM can solve it!

1 Fused surface have a stable seal.

2 No impact to inner parts as no vibration.

3 Reverse fusion (separate the parts) by applying current to heating element again.

4 Can improve work environment (no noise, high temperature and odor)

5 Fusion is consistent and even.

6 Can process complicated shape.

The features of FLAT FUSION SYSTEM

No solvent required

No screw

No vibration

Easy separation (reverse)

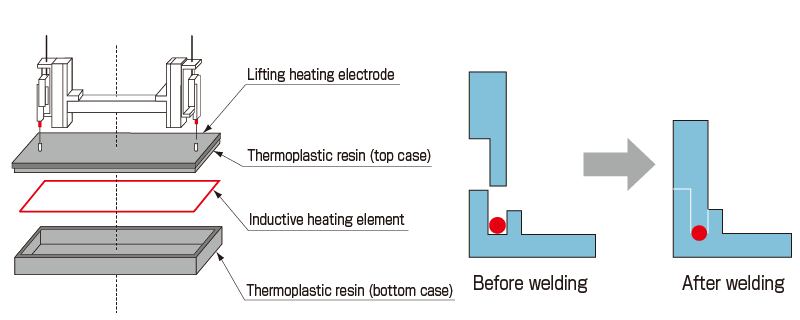

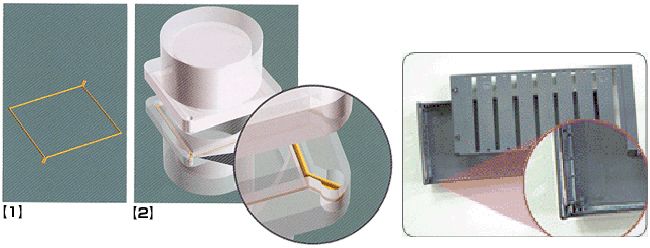

The mechanism of FLAT FUSION SYSTEM

1. Set conductive heating element between thermoplastic parts and apply current to generate heat which fuse and bond the plastic parts.

2. Between the parts achieve a perfect hermetic seal which afford something extra other bonding process cannot create.

3. Joule heat fuse thermoplastic.

4. Press and bond plastic part together.

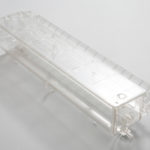

Flat Fusion System examples of use

-

- Ex.wire removal method ○Heating element (wire) pulled out after welding ○Heating element (wire) not left in product

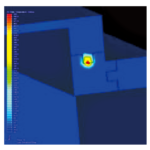

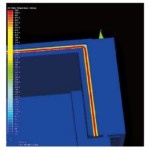

Temperature analysis simulation

Applicable plastics

■ABS ■PP ■PS ■PE ■PC ■POM ■PMMA ■ABS/PC、

■PBT ■PPS ■PPA ■PET ■PA ■LCP ■PPO ■AS etc

※現在までの溶着実績

※ガラス繊維入りの材料も溶着可能です(要相談)