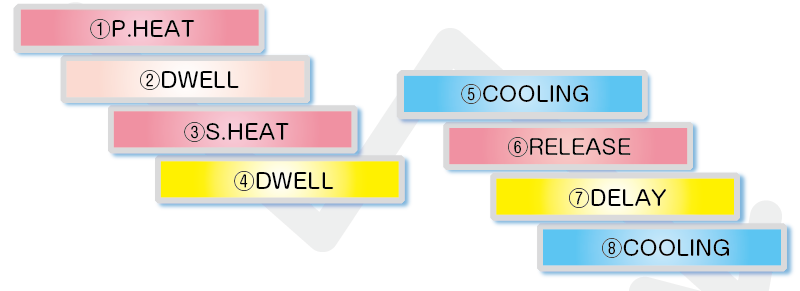

The mechanism of IMPULSE WELDER

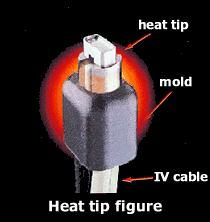

Apply electrical current to heat tip and heat tip is heated up by Joule heat.

After melting and forming thermoplastic, cool air blow solidify plastic.

Many points can be staked simultaneously. Even 100 points in the same time as 1 point.(Time may vary with size of heat tip)

IPW examples of use

The possibilities are endless.

The IMPULSE WELDER is already building a record in a range of applications. It can accommodate all kinds of needs depending on how it is used.

※Click to see sample photo

Applicable plastics

■ABS ■PP ■PS ■PE ■PC ■POM ■PMMA ■PBT ■ABS/PC ■PPS ■PPA ■PET ■PA etc

Applicable for plastic with glass-fiber.(need detailed study)

Handy Machine

+hand grip

+ [Slide unit] +lever press ,robot.

+ [Slide unit] + Built in the equipment.

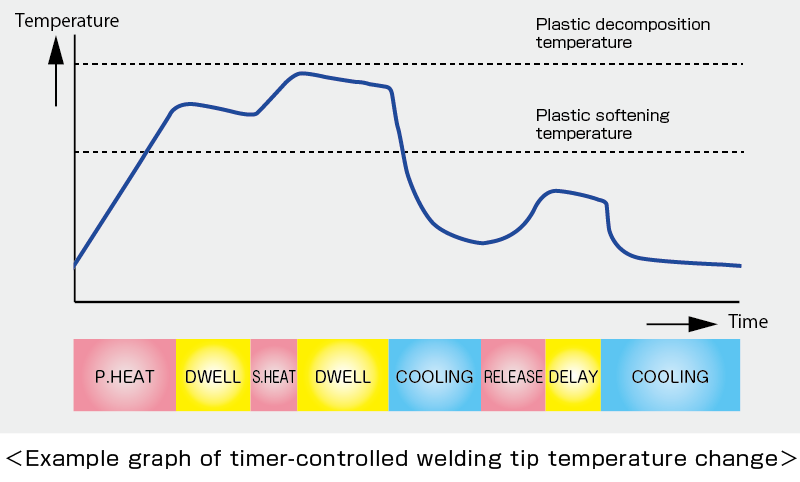

■Timer control type

MIW71-1

【Features】 <Options available>

1. Temperature indication for heat tip with thermocouple.

2. Error signal output, program selection, air pressure sensing (need sensor)

3. Support special heat tip

4. Buzzer for release timing

■Grip type Manual Operation Type: (Thermo couple not provided)

■Slide Unit Type Hand Press attached to the welding unit.

| Input voltage | AC100V |

|---|---|

| Power consumption | 265W |

| Air pressure | 0.4MPa~0.5MPa |

| Welding time | 5 to 15 sec |

| Welding tip size | Standard o 2 to o 7 (reference) |

| Product dimensions | 304(W)X212(D)X130(H) |

| Product weight | 6.5kg |

MIW71-2

【Features】

1. Temperature indication for heat tip with thermocouple.

2. Error signal output, program selection, air pressure sensing (need sensor)

3. Support special heat tip

4. Buzzer for release timing

■Slide Unit Specification Tip Block Type

| Input voltage | AC200V |

|---|---|

| Power consumption | 364W |

| Air pressure | 0.4MPa to 0.5MPa |

| Welding time | 5 to 15 sec |

| Welding tip size | Special heat tip |

| Product dimensions | 400(W)X330(D)X160(H) |

| Product weight | 12.5kg |

MIW72-1

【Features】Two-point welding control compatible

Can display temperature of welding tips with piles

1. Error signal output, program selection,

air pressure sensing (sensor needed) specifications

2. Tip temperature is voltage output

3. Buzzer for release timing

■Slide Unit Specification Tip Block Type

| Input voltage | AC100V |

|---|---|

| Power consumption | 455W |

| Air pressure | 0.4 MPa to 0.5 MPa |

| Welding time | 5 to 15 sec |

| Welding tip size | Standard o 2 to o 7 |

| Product dimensions | 400(W)X330(D)X160(H) |

| Product weight | 14.0kg |

MIW72-2

【Features】Two-point welding control compatible

1. Can control 2 staking points

2. Temperature indication for heat tip with thermocouple.

3. Error signal output, program selection, air pressure sensing (need sensor)

4. Heat tip temperature voltage output

5. Buzzer for release timing

■Slide Unit Specification Tip Block Type

| Input voltage | AC200V |

|---|---|

| Power consumption | 707W |

| Air pressure | 0.4MPa to 0.5MPa |

| Welding time | 5 to 15 sec |

| Welding tip size | Supports special heat tip. |

| Product dimensions | 400(W)X330(D)X160(H) |

| Product weight | 18.5kg |

■Temperature control / Timer control type(Dual functional)

MIW81-1/MIW81-2

【Features】

1. Temperature control / Timer control type(Dual functional)

2. When thermocouple failed, same heating profile by temperature control can be replicated by timer control with profile recording function..

3. Error signal output, program selection, air pressure sensing (need sensor)

4. Heat tip temperature voltage output

5. Buzzer for release timing

| Input voltage | AC100V/200V |

|---|---|

| Power consumption | 270W to 370W |

| Air pressure | 0.4MPa to 0.5MPa |

| Welding time | 5 to 15 sec |

| Welding tip size | Supports special heat tip. heat tip size o 2.5 to 7 (Boss diameter around o 2 to 5) |

| Product dimensions | 333(W)X280(D)X160(H) |

| Product weight | 9kg/12kg |

* We have discontinuedMIW50 series due to new model launch.

Multiple Points Machine

Large numbers of points can be welded simultaneously in a short time and with high reliability. Make to order, the machines can be built to your specifications.

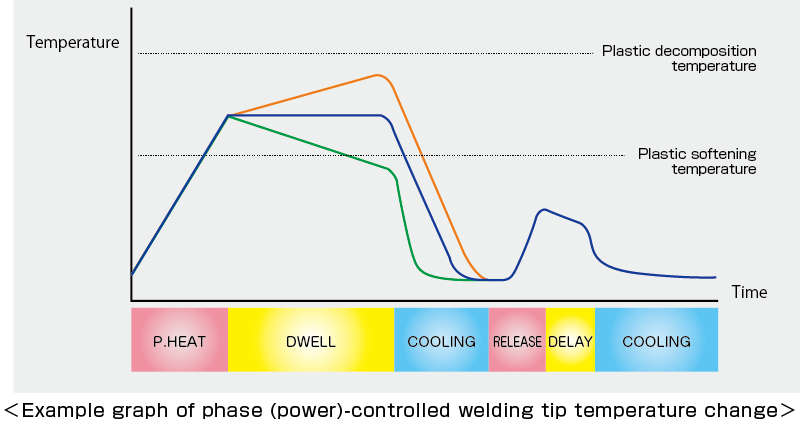

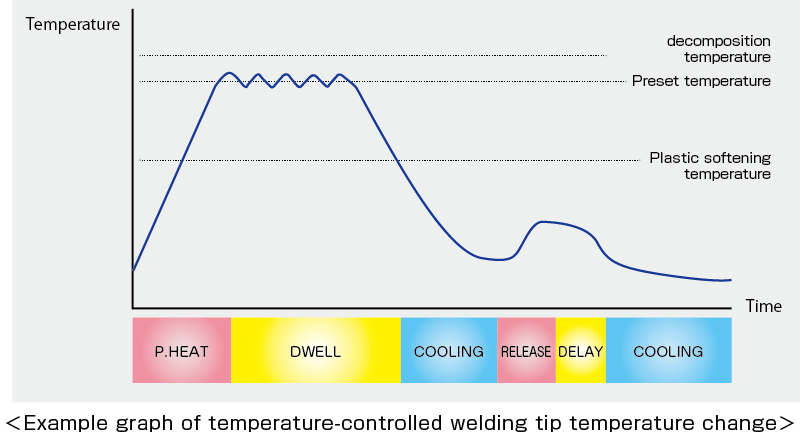

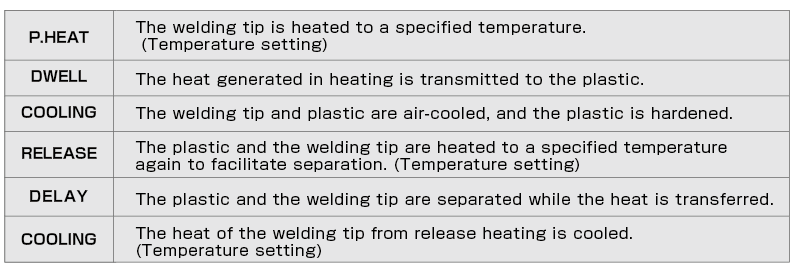

3.Temperature control method

Power supply voltage fluctuation can also be addressed (using limits for fluctuation).